Adsorbents

The pioneer of cooking and lubricant oil purification technology Activated Bleaching Earth

GALLEON EARTH™/GALLEONITE™

-

-

GALLEON EARTH and GALLEONITE are types of activated bleaching earth that are manufactured from bleaching earth, which mainly consists of fine quality montmorillonite produced on the coast of Japan Sea. By processing bleaching earth using mineral acids, the activated bleaching earth with a large specific surface area and a porous structure is obtained. Activated bleaching earth excels in adsorption and bleaching capabilities. Also, due to quite high activity, it is used in the various roles, for example as a catalyst, and meets a wide variety of needs.

GALLEON EARTH is accredited as a food additive and is used to purify various food products.

Innovative Technologies That Support the Future of Our Customers.

-

Our products are produced based on the productization technologies of natural materials that have been cultivated over many years. We manufacture the activated bleaching earth with a stable high adsorption capability using an acid process technique that is thoroughly optimized by our original manufacturing method. Customers’ longtime patronage of our products and our achievement of the No.1 domestic shipment volume are indicative of our stable manufacturing capabilities.

-

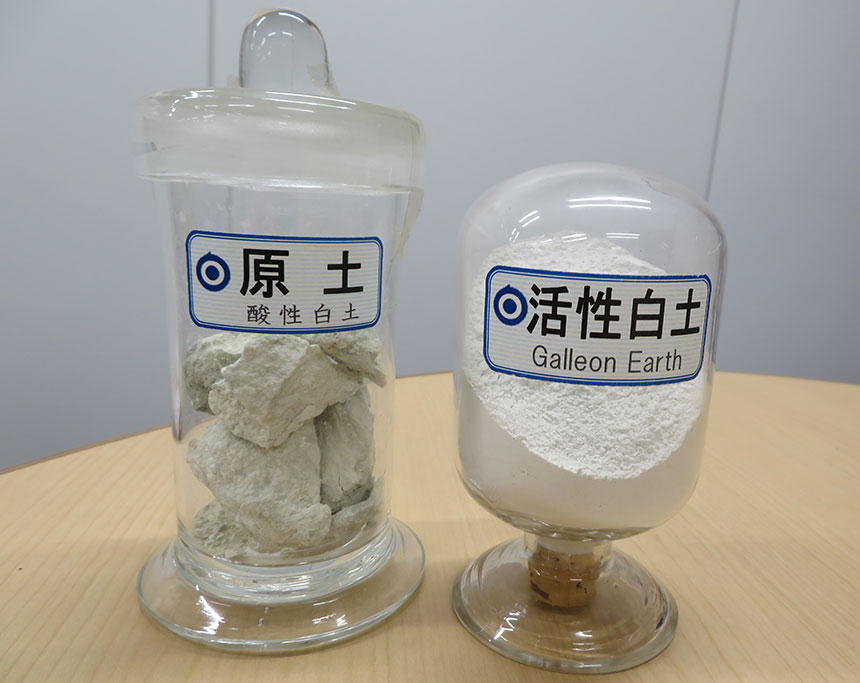

left:Bleaching earth

right:Activated bleaching earth

Products (typical grades)

Activated bleaching earth has two types: GALLEON EARTH (powder type) and GALLEONITE (granular type).

We arrange the conditions of processing, such as the acid process, to change their specific surface area, pore volume, and particle size, and make products that respond to a wide variety of needs.

-

GALLEON EARTH V2

-

GALLEONITE #136

Grades and Typical Properties of GALLEON EARTH

| V2R | V2 | NVZ | NV | ||

| Loss on heating (110℃) | % | 10.0 | 10.0 | 10.0 | 10.0 |

| Fineness (90 μm sieve passing rate ) | % | 83.5 | 94.5 | 85.0 | 90.0 |

| Specific surface area | m2/g | 305 | 290 | 250 | 250 |

| Pore volume | cm3/g | 0.48 | 0.46 | 0.35 | 0.40 |

| Average pore diameter | Å | 63 | 63 | 56 | 64 |

| Acidity | mg KOH/g | 1.2 | 1.2 | 0.8 | 0.8 |

| pH | - | 3.4 | 3.3 | 3.7 | 3.7 |

| Bulk density | g/cm3 | 0.61 | 0.61 | 0.71 | 0.69 |

Grades and Typical Properties of GALLEONITE

| #251 | #212 | #136 | ||

| Loss on heating (110℃) | % | 10.0 | 10.0 | 10.0 |

| Specific surface area | m2/g | 290 | 285 | 290 |

| Pore volume | cm3/g | 0.45 | 0.42 | 0.46 |

| Average pore diameter | Å | 62 | 59 | 63 |

| Acidity | mg KOH/g | 1.0 | 1.0 | 1.0 |

| pH | - | 3.0 | 3.5 | 3.5 |

| Bulk density | g/cm3 | 0.63 | 0.64 | 0.65 |

| Granularity | mm | 4.0-1.7 | 1.7-0.71 | 0.71-0.25 |

Typical Usage

Oil/fat purifier

Activated bleaching earth is used to purify oils and fats. The adsorption capacity of activated bleaching earth removes colored substances, such as pigments, and impurities in oil or fat. It is applied to purify various types of edible oils (e.g., vegetable oil, lard, and margarine) and mineral oils (e.g., lubricant, engine oil, and transformer oil). It is also used to purify cleaning solvents.

Catalysts/Industrial adsorbent

Activated bleaching earth is also used to remove very small amounts of unsaturated compounds produced during the manufacture of benzene, toluene, and xylene. The activated bleaching earth has a catalyst capability that alkylates or polymerizes unsaturated compounds to remove them as heavy ends. In addition, it is used as an industrial dehydrating agent, an adsorbent of dioxin released from a garbage incineration plant, and a carrier for agricultural chemicals.

Physical and Chemical Characteristics

-

-

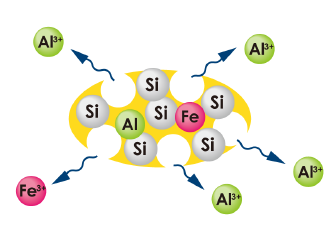

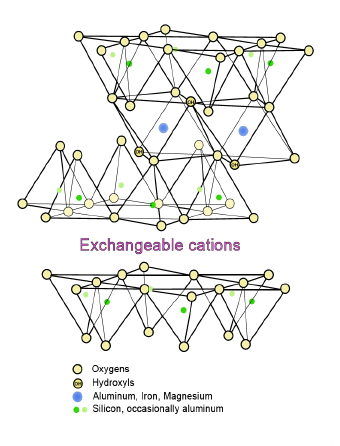

Our factories are located in western coast of Yamagata and Niigata Prefectures in Japan, which produce an abundant fine aluminosilicate bleaching earth mineral (montmorillonite). Montmorillonite has a three-layer structure comprising an alumina layer sandwiched between silica layers. Part of the aluminum atoms in the alumina layer are replaced with those of a divalent metal (isomorphous replacement), rendering each layer’s positive charge insufficient, and therefore positive ions, such as those of sodium or calcium, present between the layers to supplement the positive charge.

We purify, acid-treat (activate) , and crush the mined crude soil to manufacture high-quality bleaching earth, activated bleaching earth, and bentonite. The main component of bleaching earth is montmorillonite, and by means of acid treatment, the bleaching earth is converted into activated bleaching earth. Acid treatment dissolves a part of the alumina layer in the structure of bleaching earth, producing fine pores and a large specific surface area. These properties demonstrate fine adsorbent and decoloring capabilities. Similar to bleaching earth, the main component of bentonite is montmorillonite. In addition to its adsorption capability, bentonite also has a high swelling and colloidal dispersion capability.